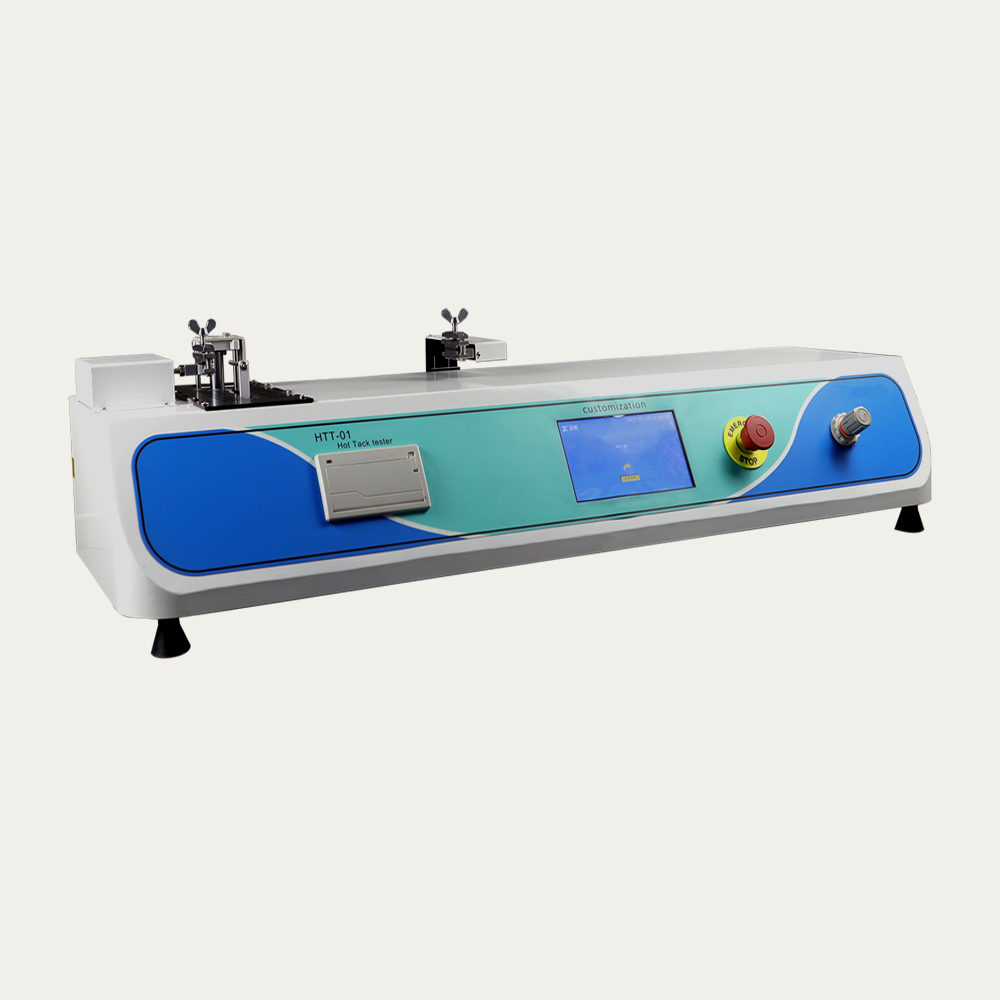

Description

HTT-01 Hot Tack Tester is applicable in hot tack and heat seal performance tests for plastic films, laminated films and other packaging materials

- Sealing Temperature Room temperature ~ 300 °C

- Temperature Accuracy ±0.2 °C

- Dwell Time (Heat Seal Test) 0.1~ 999.9s

Temperature Uniformity ± 1 °C

Dwell Time (Hot Tack Test) 0.1~ 999.9s

Sealing Pressure 0.05 MPa ~ 0.7 MPa

Sealing Area 100 mm ×5mm

Heating Mode Single or Double Heating Surfaces

(Customization)

Gas Supply Pressure 0.5MPa~0.7MPa (Not in Supply Scope)

Port Size Φ4mm PU Tubing

Load Cell Capacity 0~200 N ( 30N, 50N, 100N, 500N optional )

Force Accuracy 0.5% FS

Force Resolution 0.001N

Test Speed 0.05 ~ 3000 mm/min

Specimen Width 15 mm, 25 mm or 25.4 mm (Customization)

Stroke 500 mm

Instrument Dimension 1170mm (L) × 360 mm (W) × 460 mm (H)

Power Supply AC 220V 50Hz / AC 120V 60HZ

Net weight 45 kg

Basic Application

- Hot Tack Performance:

Plastic films, sheets and composite films e.g. PE, PP, PET and composite films used in packages for instant noodle, milk powder, washing powder, food and drugs - Heat Seal Performance:

Plastic films, sheets and composite films - Tensile Strength:

Tensile strength test of various films, sheets and composite films - Peel Strength:

Adhesives and adhesive tapes

Extended Application

- Medical Adhesives:

Peeling test and tensile strength test of medical adhesives e.g. adhesive bandages - Adhesive Tapes:

Low speed unwrapping test - Textiles, Nonwovens and Woven Bags:

Peeling test and tensile strength test - Protection Films:

Peeling test and tensile strength test - Magnetic Cards:

Peeling test of the films and magnetic cards - Bottle Caps:

Opening force test of the aluminum plastic

combination bottle caps

ASTM F1921, ASTM F2029