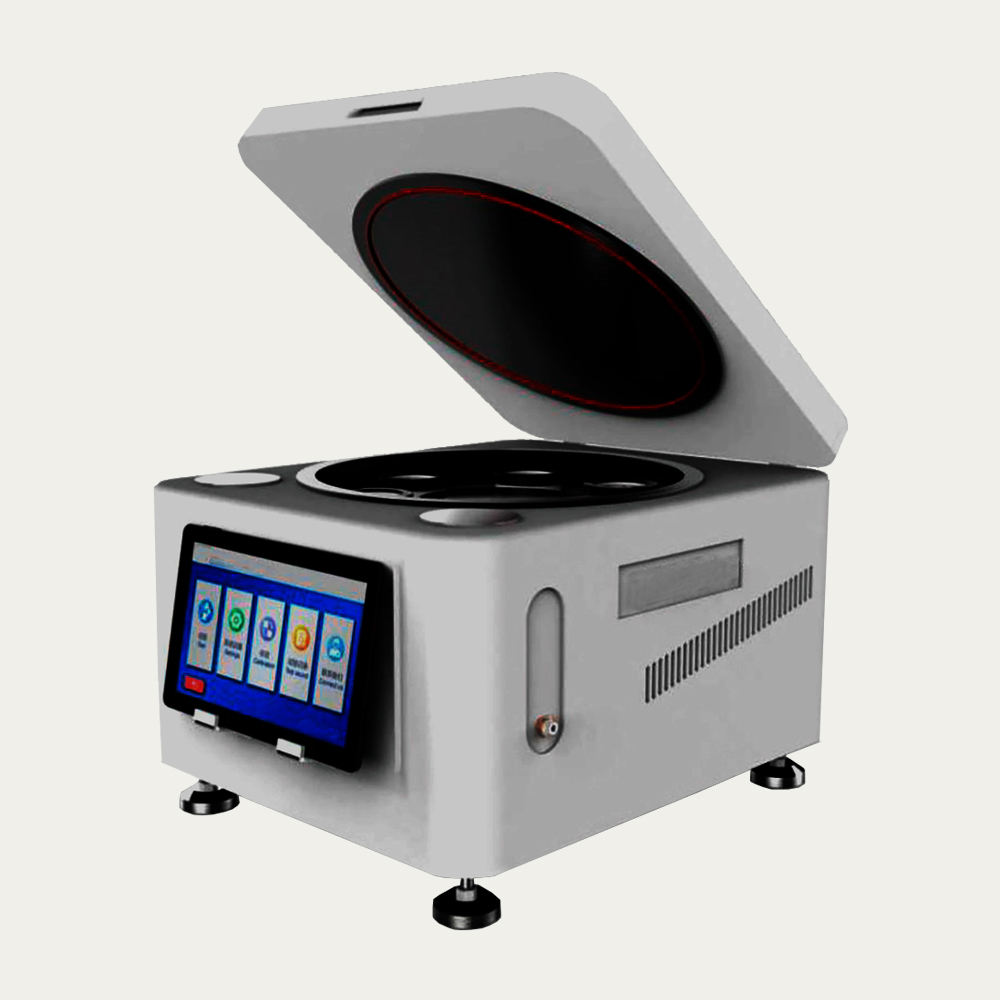

Gas Permeability Meter GTR-G3 (Difference Pressure Method – 3 Samples)

Description

The GTR-G3 gas permeability meter is based on the differential pressure method and is professionally applicable to the determination of the gas transmission rate (GTR).

- Test range: 0.05~50,000 cm3/m2·24h·0.1MPa (standard volume)

At least 500,000 cm3/m2·24h·0.1MPa (extended volume) - Number of samples: 3

- Number of sensors: 3

- Test mode: three independent chambers

- Vacuum resolution: 0.1 Pa

- Test chamber vacuum degree: <20 Pa

- Test temperature: 5°C~95°C ±0.1°C (dry gas at standard temperature)

- atmospheric pressure)

- Temperature accuracy: ±0.1℃

- Test pressure: -0.1 MPa ~ +0.1 MPa

- Gas supply pressure: 0.1 MPa ~ 0.8 MPa

- Test gas: O2, N2 and CO2 (out of scope of supply)

- Carrier gas interface: Ф6

- Vacuum tube diameter: 1/4″

- Correction method: standard film calibration, external vacuum sensor calibration

- Sample thickness: ≤3mm

- Sample size: Φ97mm

- Test area: 38.48 cm2

- Instrument dimensions: 740mm (L) x 415mm (W) x 430mm (H)

- Power supply: AC 220V 50Hz.

- Net weight: 50kg

Basic applications

- Films:

Including plastic films, plastic composite films, paper-plastic composite films, co-extruded films, aluminized films, aluminum foils, aluminum foil composite films and many others. - Sheets:

Including technical plastics, rubber and construction materials, e.g. PP, PVC and PVDC

Extended application:

- Petrochemistry:

Including transport pipes, such as CO2 testing on MDPE plastic. - Various gases:

Test the permeability of various types of gases, e.g. O2, CO2, N2, Air and He - Flammable, Explosive:

Test the permeability of flammable and explosive gases. - Gas biodegradable films:

Test the gas permeability of various types of biodegradable films, e.g. starch-based biodegradable bags - Materials for aerospace use:

Test Helium Permeability of Airship Gas Bags - Paper and paperboard:

Test the gas permeability of paper and paper-plastic composite materials, e.g. aluminized paper for cigarette packages, Tetra Pak foils, paper instant noodle bowls and disposable paper cups - Paint films:

Gas permeability test of substrates coated with paint films. - Fiberglass cloth and paper:

Including fiberglass fabrics and paper materials, e.g. Teflon paint cloth, Teflon welding cloth and Teflon silicone rubber cloth - Materials of soft tubes for cosmetics:

Including various types of cosmetic tubes, aluminum and plastic tubes and toothpaste tubes. - Rubber sheets:

Including various types of rubber sheets, e.g. auto tires - Vacuum packaging:

Including vacuum packaging manufacturing sheets that are easily susceptible to oxidation and gas corrosion, such as electronic products, such as consumable sensors, etc.

ASTM D1434, ISO 2556, ISO 15105-1