Share on:

Which are the main differences?

In the field of packaging, transportation and storage, corrugated boxes undergo various stresses that can pose a threat to the enclosed products. Testing methods like the Edge Crush Test (ECT) and Burst Strength Test enable companies to anticipate these challenges and tailor protective packaging accordingly.

The common dilemma faced by companies revolves around choosing between ECT and Burst Strength, two prevalent testing methods for evaluating the strength of corrugated material. Despite their common use, these tests serve distinct purposes and measure different aspects. This analysis aims to highlight the disparities between the Edge Crush Test and Burst Strength Test, offering guidance on when each test should be applied based on a company’s specific requirements.

ECT – Edge Crush Test

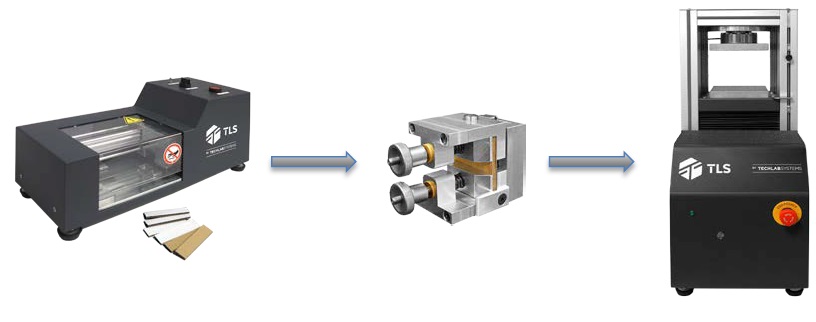

The Edge Crush Test (ECT) is a standardized laboratory test method that it is used to measure the cross-direction crushing of a corrugated board sample. To perform an ECT test, a force is applied perpendicularly to the specimen at a constant speed of 12.7 mm/min until it collapses.

The ECT is a true performance test and is directly related to the stacking strength of the boxes. It is measured in different units like lb/in, kN/m, etc.

ECT Applicable Standards: APPITA/AS 1301.444s, DIN EN ISO 3037, FEFCO 8, ISO13821, SCAN P33, TAPPI T811, TAPPI T823, TAPPI T838, TAPPI T839

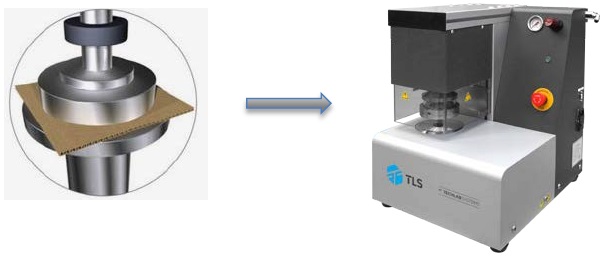

For a long time, the Mullen Burst test has been an important technique for measuring the durability and strength of corrugated and flat carboard. A Burst Strength Tester uses a pressurized diaphragm to measure how much pressure (in PSI, Kg/cm2, kPa or Bar) the side of a corrugated box can take before it breaks.

Packaging with high burst strength is essential to ensure that the product reaches its destination in good condition, without puncturing or damaging the packaging during transportation. The Mullen test, which relates burst strength to grammage, allows for comparing different qualities of cardboard

Applicable Standards: DIN EN ISO UNE 2759 – FEFCO No 4 – SCAN P25 – TAPPI T807 – TAPPI T810 – BS 3137 – PAPTAC D.19 – APPITA AS 1301.438

When should you use each test?

1. Suitable for companies with stacking and palletizing in their distribution cycle.

2. Ideal for transporting goods without lateral forces and exposure to multiple shipping modes.

3. Does not require a minimum amount of base paper, allowing for lighter boxes.

4. ECT-rated boxes are generally lighter, potentially reducing shipping costs and environmental impact.

Mullen Burst Strength Test:

1. Suitable for companies concerned about improper handling and goods likely to move inside the box.

2. Calculates resistance force when shipping goods that may exert force on the side walls.

3. Requires a minimum basis weight of the paperboard, ensuring a certain level of strength.

4. Necessary for scenarios where rough handling is expected during transport.

The elimination of the minimum basis weight requirement in the ECT allows for the use of lighter materials while still maintaining high performance.

#TRUETESTING

Compartir en: