Automatic Shock Test Systems – AutoShock II™

Description

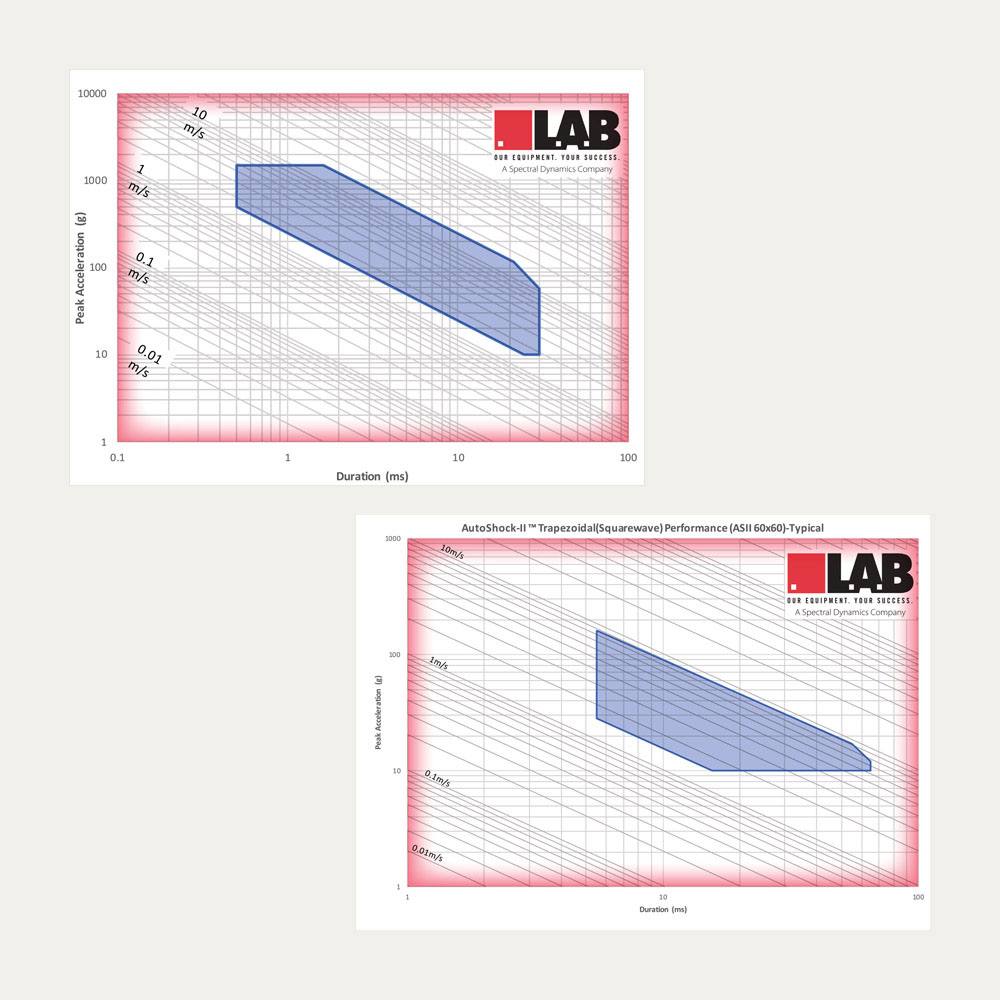

AutoShock-II™ is a fully automated shock test system used to measure and identify product fragility levels and evaluate protective packaging. These systems perform a wide variety of half sine, square or saw-tooth waveform impacts. With the simulation of real world shock pulses and impact energy levels, manufacturers can systematically test and optimize product design and packaging.

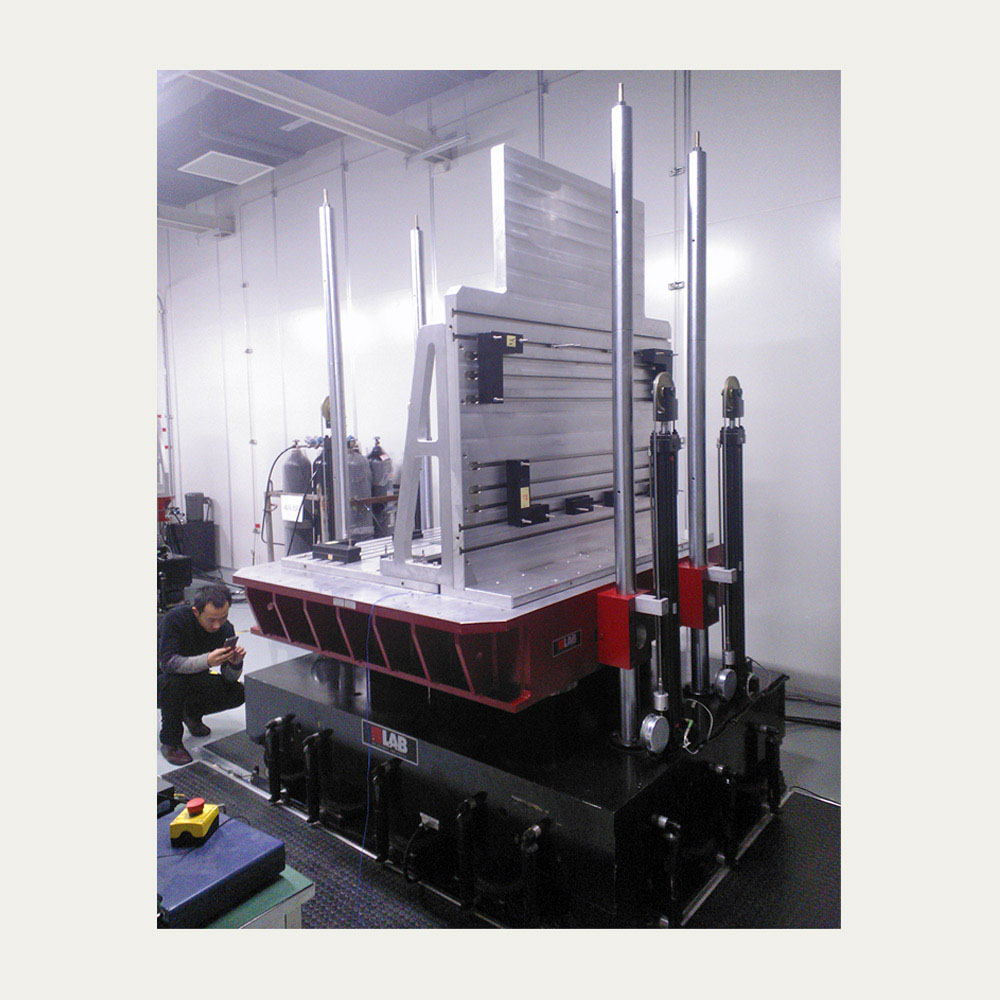

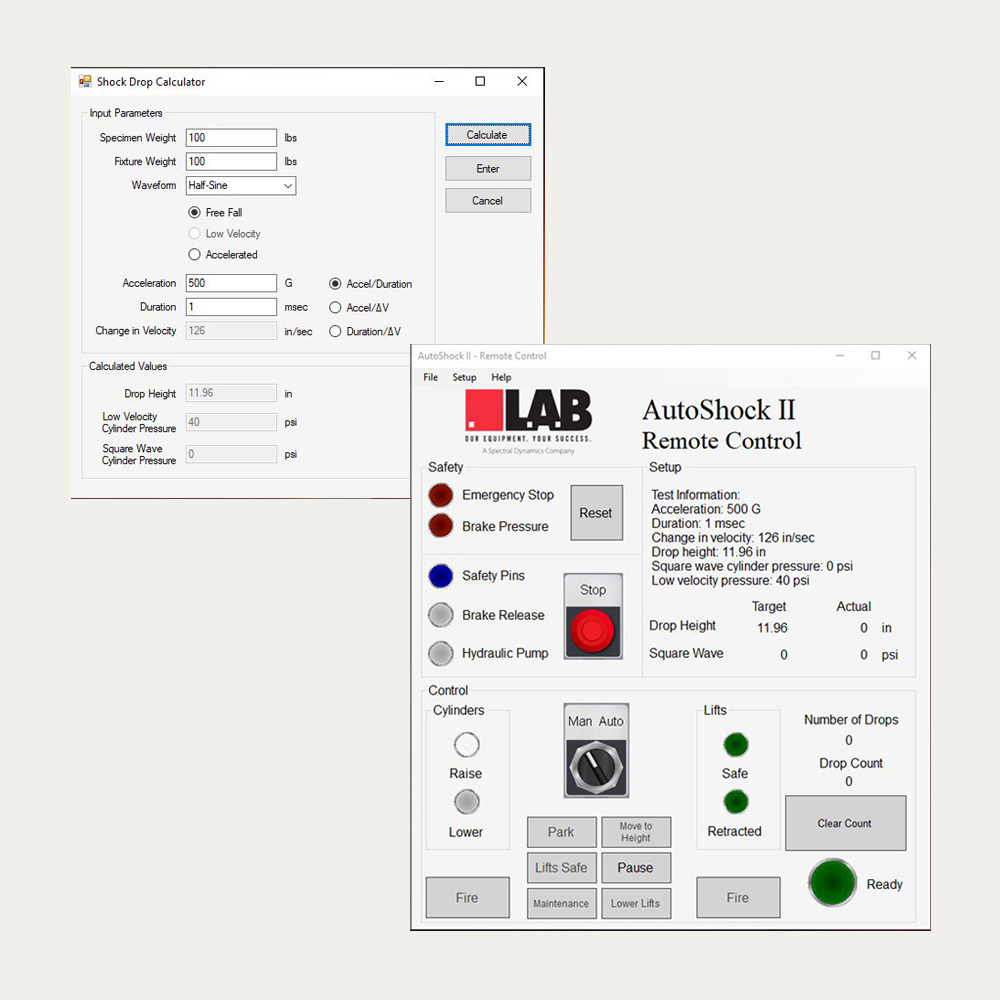

- Windows 10 based PC control system with intuitive remote control interface automates procedures and reduces test times. The operator simply enters conditions and AutoShock-II™ converts them into specific machines instructions and performs the test.

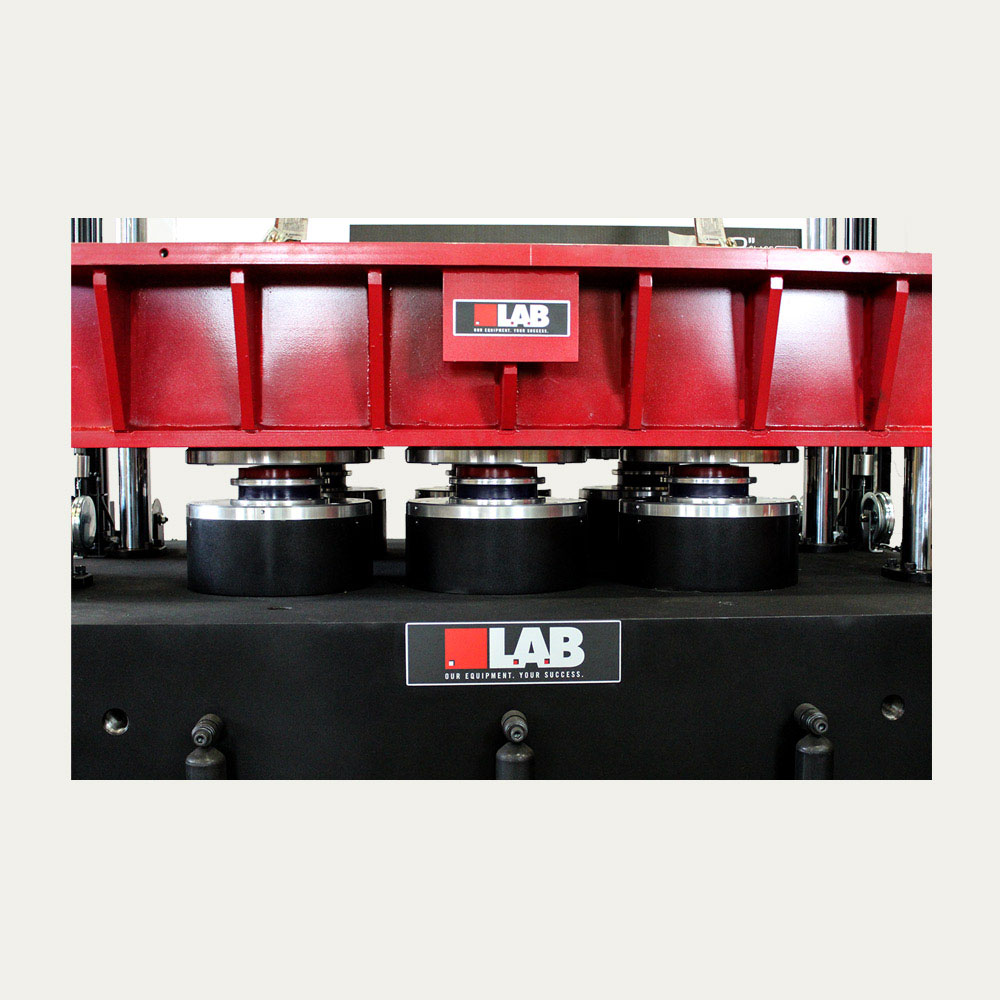

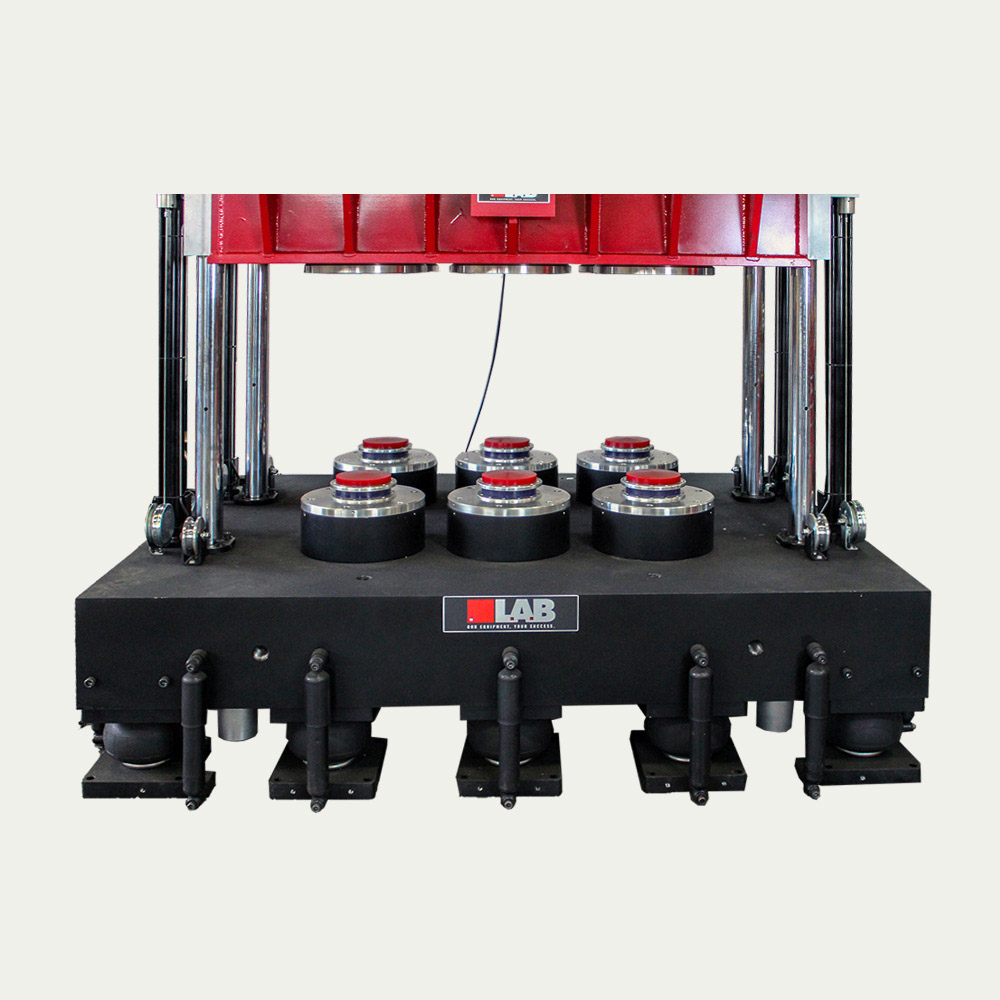

- A multiple post guidance system with balanced hydraulic lift cylinders provides automatic, chatter free positioning and alignment of the shock table.

- An automated shock drop calculator simplifies the determination of drop heights and pressures to quickly achieve the operator’s requested shock pulses. Drop heights and pressures can be stored and easily retrieved.

- High performance cast or welded aluminum tables produce optimum table strength and stiffness with minimal table noise and eliminating the need for over filtering of shock test data.

- A state-of-the-art braking system eliminates secondary impact rebounds and provides a secure and reliable method of holding table position prior to the drop.

- Food and Beverage Industry

- Pharmaceutical and Cosmetic Industry

- Electronic industry

- Chemical industry

- Home appliances

- Computers – Smart TV…

OEM, ASTM, MIL-STD, IEC, and ISO