See you at HISPACK 2024

Next week the HISPACK 2024 Show will be held, the most important meeting point in the packaging ecosystem in Southern Europe. Over 4 days, thousands of professionals and exhibitors from the packaging world make us their meeting point, a superb showcase to discover the solutions and trends that set the course for the industry.

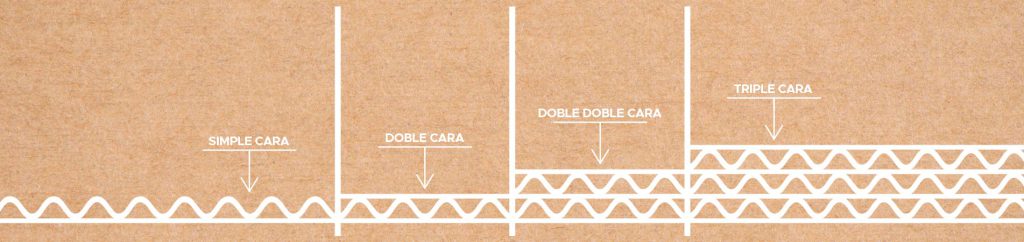

Companies and professionals from various industries come to present their new products at an event that generates business opportunities, encourages new collaborations and supports knowledge and innovation to promote packaging as a lever for sustainable growth. One more edition, TECHLAB SYSTEMS will be part of the exhibitors at HISPACK 2024 and will present the latest developments and advanced technology for carrying out quality control laboratory tests on all types of packing and packaging (paper, corrugated board, flexible packaging, plastic packaging, metal containers, etc.).

We invite you to join us at Hall 2 Stand E-221, where our experts will show you different technics and laboratory instruments for packaging like:

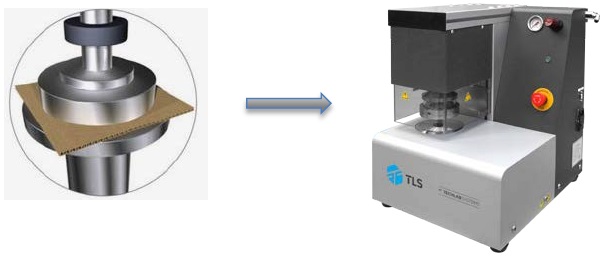

- Box Compression Tester VALIDATOR PLUS to determine the BCT compression strength in packaging and simulate stacking and fatigue tests

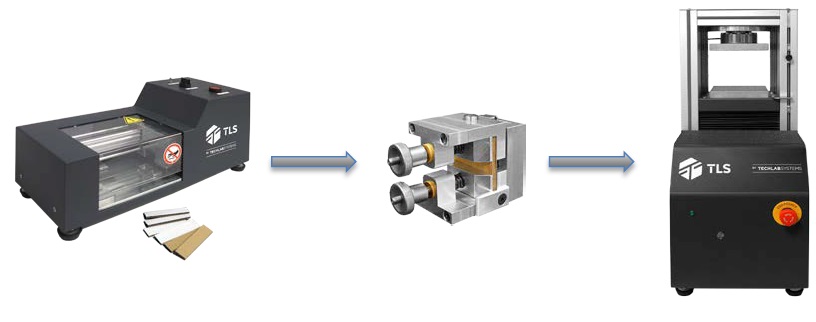

- Samples Crush Tester CDM-5 with ECT accessories.

- Sample Cutter CM to prepare with precision ECT and PAT samples.

- SCT Tester to determine the short compression strength on papers.

- Wet ShearAdhesion Tester WS-21 to determine the determine the resistance of glues in corrugated board by water immersion.

- Universal Testing Machine MTE-1L with different accessories to measure the tensile strength and elongation of several materials, friction tests, box opening force tests and others.

- Melt Flow Indexer MFI-500/AP to determine by gravimetric and volumetric methods how thermollastic material flows.

- Elmendorf Tearing Testes FTS-01 to determine the tear strength on different materials

- Ultra MicroCast Line LUMCR-50

#TRUETESTING